Guarantees that we will refund you the difference if you find a lower price from us within 30 days of your purchase.

Free Local Shipping

2-year Hassle Free Warranty

Lifetime Customer Support

Garbage compactor truck is the most popular type for waste management companies. It is mainly suitable for the collection and transportation of garbage in various places such as municipal sanitation, property management, large-scale factories, industries, and mines. CLW Group has more than 18 years experience on design and produce garbage trucks which including garbage compactor truck, Hook Lift Garbage Truck, swing arm Garbage Truck .

Main feature

1. Truck chassis: ISUZU,Dongfeng, HOWO,Foton, Shacman, JAC, JMC, FAW, CAMC etc.

2.Types of models: single axle, front four rear four, front four rear six, rear eight wheels, front four rear eight, second axle semi-trailer, three-axle semi-trailer, etc.

3. Garbage bin box size various from 5cbm, 6cbm,8cbm,10cbm, 12cbm, 14cbm, 16cbm, 18cbm, 20cbm, 22cbm, 25cbm, 30cbm, 35cbm,45cbm .

4. Garbage bin box material: high intense carton steel, from Well-known steel mills in China.

5. PLC control system from driver cabin and rear side of truck, easy operate by the workers.

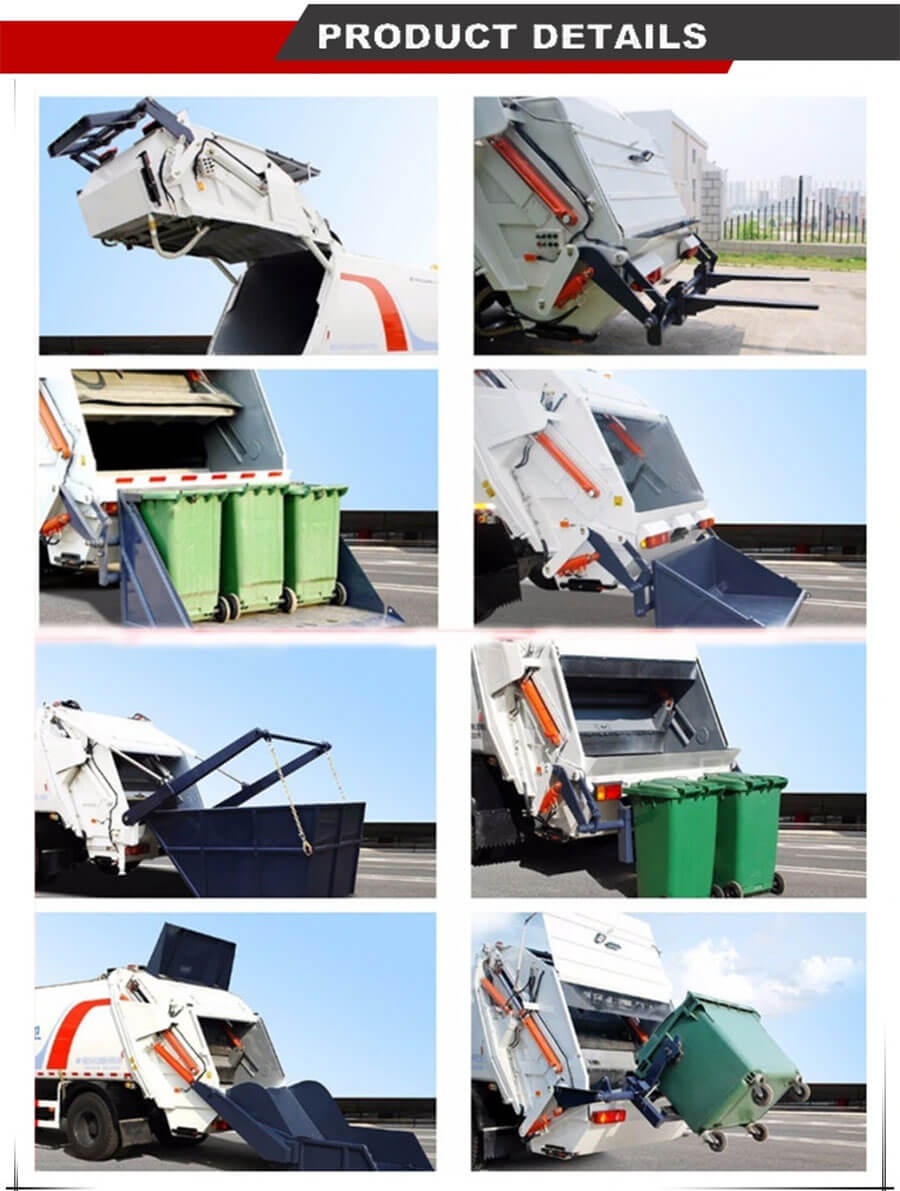

6. multi type rear loading type for choice, customized design based on user's need.

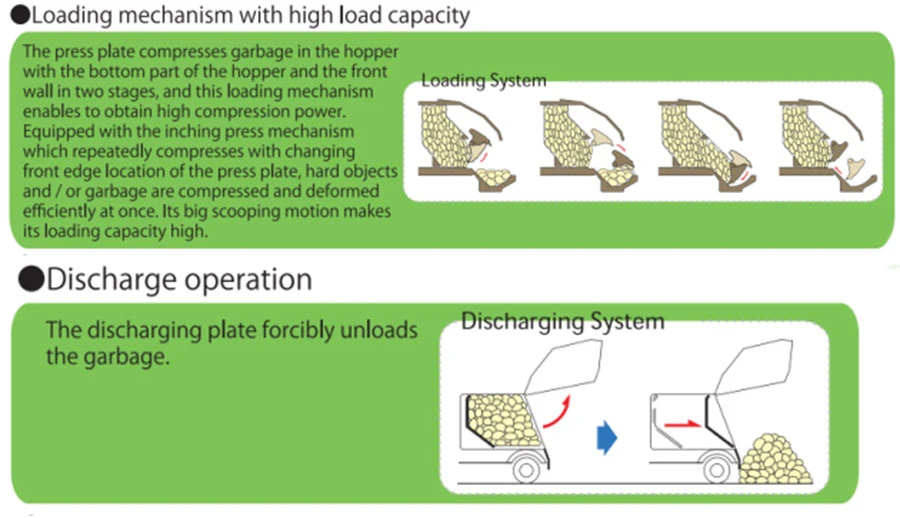

7. High efficient compression rate 0.6 to 0.8 depends on the waste type.

8.The garbage can be completely compressed by the full hydraulic control operating system.

9.The utility model can realize the combined operation of a car and a plurality of garbage compartments, circulate transportation, and fully improve the transportation capacity of the vehicle

Our garbage Compactor truck has the features :

a. reasonable structure,simple and stable operation; High efficiency; Good sealing performance; Easy Dumping;

b. With dump function and hydraulic operation, very easy to collect the garbage;

c. The lifting mechanism use the lifting base support device, which can decrease the error generated during the preparation, make the mechanism move smoothly, and extend the service life of the lifting mechanism.

d. The sliding block of the ejector is made of high wear resistance alloy material with long service life.

Optional for different methods of waste collection which should be confirmed with us, different type, the cost is different:

| NO. | Name | Structure and performance characteristics |

| 1 | Trash Bin | Optional for 120/240、660L plastic trash bin Or 330Lsteel material trash bin. |

| 2 | Manual and pneumatic sealing cover | Optional for 120/240、660L plastic trash bin.

|

| 3 | Triangle trash hopper | Optional for 120L、240L plastic trash bin. Hopper inside can load two 240L plastic trash bin.

|

| 4 | All-sealing trash hopper | with large landing bucket, have high operation efficiency and self sealing function

|

| 5 | Swing arm system with hopper. | With the swing arm dustbin (with a volume of about 2.5-3m3), multiple dustbin collection points can be placed in one plant area.

|

The CL Semitrailer Hydraulic Garbage Compactor is specifically designed for the transfer of waste from inner city locations and intermediate stations to long-distance solid waste storage areas. This type of semi-trailer is available with loading capacities ranging from 40 m³ up to 90 m³ and is commonly referred to as a Waste Transfer Semi Trailer or Garbage Compactor Semi-Trailer.

The Compactor Garbage Truck tank upper body is mounted on a 3-axle trailer chassis and features a tank made of high-strength, wear-resistant steel plates. Other components include a hopper composed of sliding plates, a sweeping panel for garbage collection and compaction, a hydraulically opening tailgate, and a garbage bin tipper. The Semitrailer Hydraulic Garbage Compactor can be controlled from the cab-in control, manual control, and push-button control.

SPECIFICATION

| DEFINITION | Net 84m3 (97+2m3) capacity Rear loading semitrailer hydraulic garbage compactor. Dimension: 13.6m x 2.44 m x 2. 59 m |

| CONSTRUCTION | Semi-Trailer chassis (subframe) Body Tailgate (rear hopper) Ejection/discharging Plate Diesel Power Unit |

| CAPACITY | Net Volume/capacity: 84 m3 - Total volume is 99 m3. Tailgate 2m3 |

| BODY STEEL | Floor/SIDE WALLS: 6mm; Roof: 4mm; UN LOADING PLATE FRONT SURFACE: 6mm |

| TAILGATE (REAR HOPPER) | Tailgate Floor, rear hopper floor extension inside body and side wall. Other areas from 6mm steel The tailgate is connected to the body with top hinges and opened upwards by means of two units double acting hydraulic cylinders |

| COMPACTION RATIO | The compaction ratio (volumetric) varies between 3: I- 6: 1 according to the characteristic and density of the garbage used in the area (above mentioned parameter is valid for household garbage) |

| HOPPER CAPACITY | The garbage capacity of the loading hopper is around 2m3 |

| COMPACTION PLATE | The inner surface of the compaction plate where garbage fabrication and compression occur is from 10mm wear-resistant steel. |

| SEALING | With a special design leak-proof rubber sea between the tailgate and the body |

| LOCKING | Hydraulic locking by means of reverse action of two hydraulic tailgate-lifting cylinders. |

| SAFETY PROPS | The tailgate is provided with safety props (manual) between the body and tailgate for safety purposes during maintenance |

| SAFETY VALVE | Equipped with an anti-dropping safety valve on the tailgate and hydraulic lines to prevent sudden falls. |

| CONTROL | All devices for loading control arc mounted on tailgate right side. The compaction mechanism can be operated electrically (automatically) via push buttons + mechanically (manual) via a hand lever. Control the tailgate (opening and closing) and forward + backward movement or the ejection plate is from the rear left side of the body. The container lifting mechanism is only by a manual control (hand lever). |

| DISCHARGE OF GARBAGE | The unloading cycle will last a minimum of 4 minutes and 30 seconds. Ejection Plate: The movement of discharging plate (panel) will be step by step in a progressive method (in stages) and will be designed against maximum 190 bar working pressure. The average working pressure is 170 bar. Locking Cylinder 063 mm x 035 mm 2 units. Locking Cylinder Working Pressure 80 bar. Ejection plate Main Cylinder 0160 mm x 0100 mm. |

| HYDRAULIC COMPONENTS | FRONT DIRECTION CONTROL VALVE (Front Distributor) MAIN SAFETY VALVE. HYDRAULIC CYLINDERS / all arc hydraulic and double-acting. The dimensions of the cylinders’ arc are designed to accomplish the stipulated cycle times and compaction ratio. Hydraulic cylinder pipes & bores included. HYDRAULIC HOSES / All high-pressure hydraulic oil hoses have an app. burst rating 4 times more than the specific system working pressure. |

| TRAILER CHASSIS | Trailer Chassis: From” H” profile steel Kingpin: In accordance with standard 3 Axles: Each axle has a 12tons lifting capacity Brake System: WABCO ABS braking system Landing Gear: 2 units’ mechanical type Tyre: 385/65 R22.5 |

FAQ

1. who are we?

We are based in Hubei, China, start from 2009,sell to Domestic Market(50.00%),Southeast Asia(9.00%),Africa(6.00%),South America(5.00%),Mid East(5.00%),Central America(4.00%),North America(2.00%),Eastern Europe(2.00%),Oceania(1.80%),Eastern Asia(1.20%),Western Europe(1.50%),Northern Europe(1.30%),Southern Europe(1.70%),South Asia(1.50%). There are total about 1000+ people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Fire Truck ,LPG Tank Truck,Fuel Tank Truck, Tank Truck ,Cleaning Truck,Garbage Truck, Tow Truck , Bucket Truck ,Construction Truck, Van Truck ,Truck Mounted Crane,Utility Truck,Tank Semi Trailer,Semi Trailer

4. why should you buy from us not from other suppliers?

Our advantages:

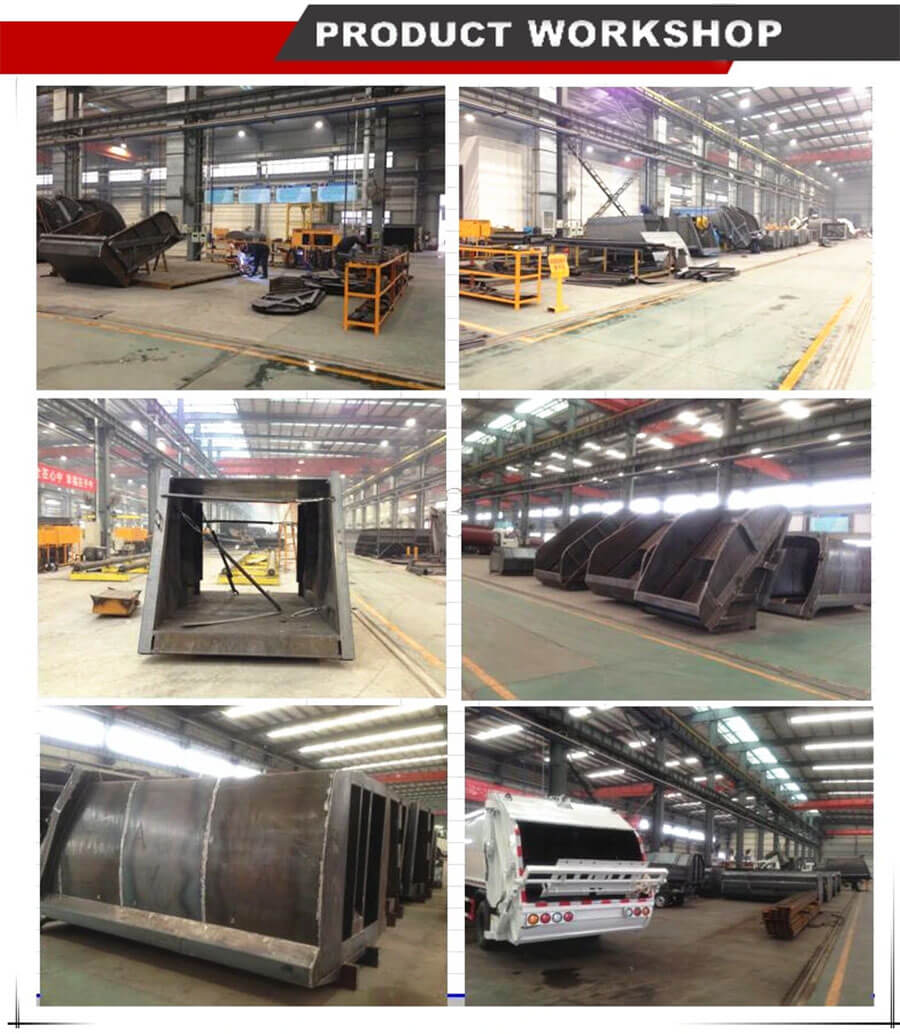

1. manufacturer & factory of special trucks in China

2. years' experience in this fields

3. owns workshop, profesional works & experienced engineers

4. complete procedure for order, production, sales,

5. national & international maket

5. what services can we provide?

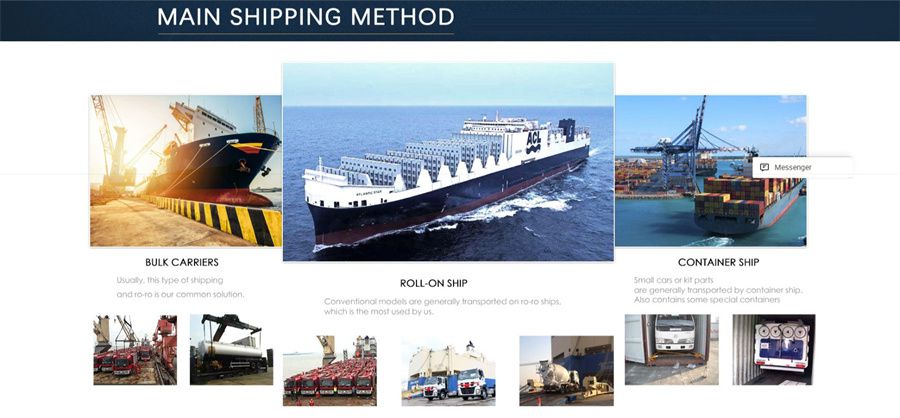

Accepted Delivery Terms: FOB,CIF,EXW,DAF,DES;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram;

Language Spoken:English,Chinese

A: We are a leading manufacture of pressure vessels,bobtails,trailers, trucks, and skid mounted stations,and spare parts. Welcome to visit us in Suizhou city, the production base of Chinese special purpose vehicles.

2. Q: Where is your factory located?

A: We are located in Suizhou City,Hubei Province,China

3.Q:How can i visit there?

A:Welcome to the factory for inspection. You can fly to Wuhan Tianhe Airport, and our company will arrange a special car to pick you up.

4.Could you customize exactly according to my requirements?

A:Yes. We have professional R&D team, we can produce the product exactly according to your requirements.

5.Q: Do you provide certification that we need?

A:We can provide various certifications associate. Such as BV,DOT, ADR, SASO and so on.

6.Q: what's your payment terms?

A:T/T& L/C are preferred.

7.Q:Do you arrange shipment for the vehicles?

A:Yes,we can arrange shippment based on trade terms.

8. Q:What service can I get from you?

A:We provide lifelong tracking service and one year free warranty for all of our products. Meanwhile we provide free training and technical support to guide you repair your product. If need, we will also send original spare parts free of charge by air.

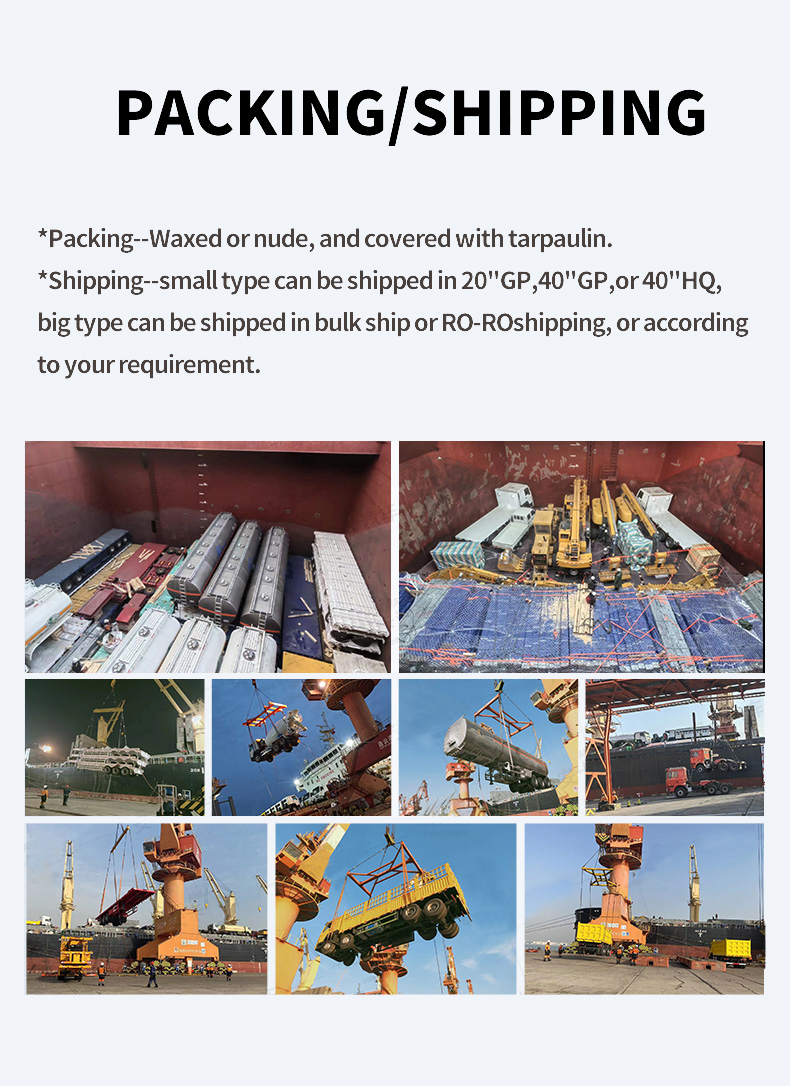

9.Q:How is the packing?

A:All the packing comply with exporting standard.

10.Q:How long is the lead time?

A:20-25 working days.

For other questiones,we will reply you ASAP after receiving your consult!